The NVRAM Manager or NvM is the AUTOSAR Basic Software service that centralizes all access to non-volatile memory in an ECU. It provides a uniform interface for application software to read write and maintain persistent data while hiding device specific memory drivers and error recovery.

The module plays a central role in ECU reliability because it controls integrity checking redundancy and coordinated writes to flash or EEPROM devices.

Table of Contents

Why the NVRAM Manager in AUTOSAR exists

Automotive software must preserve calibration parameters counters and state across power cycles and maintain data integrity in the presence of interrupts power loss and flash wear. AUTOSAR provides the NVRAM Manager to:

- Isolate application code from hardware specific memory drivers.

- Coordinate concurrent requests and schedule memory operations to respect device timing constraints.

- Provide block level integrity checks and redundancy options.

- Offer synchronous and asynchronous service interfaces for different use cases.

NV Blocks and Block IDs

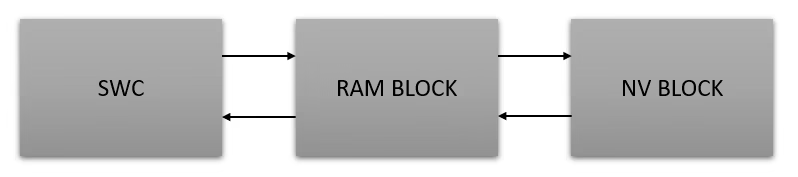

When writing data, the SWC sends data to a RAM block, and from there it is saved to NV memory. When reading data, the process is reversed: data moves from the NV block to the RAM block, and the SWC reads it from the RAM mirror.

NV blocks are used to store non-volatile data in NV memory. Each block is assigned a unique Block ID, which is defined and managed in the NV Block Descriptor Table.

For example, vehicle speed data such as maximum speed and minimum speed, which can be displayed on the car’s console, is stored in NV memory within a dedicated NV block for speed parameters.

This block is identified by its Block ID. In the same way, error information can be stored in a separate NV block created for vehicle errors, with its own Block ID assigned through configuration tools.

Position of NVRAM Manager in AUTOSAR stack

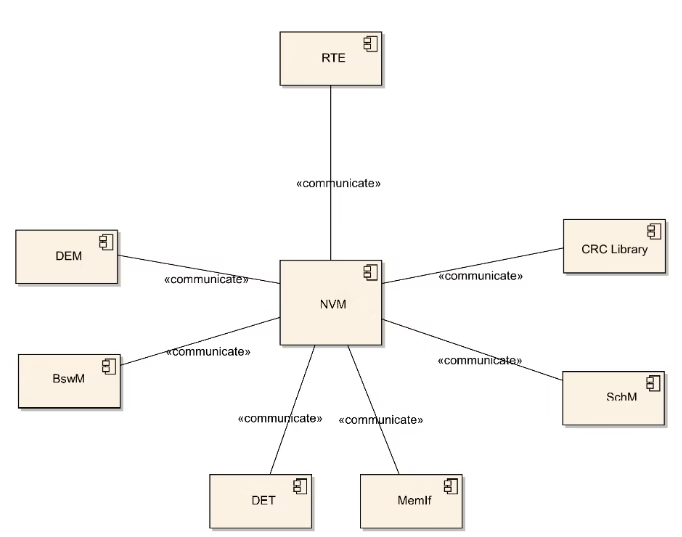

NvM belongs to the Basic Software services layer in the Classic Platform. SW components access NvM via client server calls through the RTE. Under NvM sits the memory abstraction layer MemIf which in turn calls device level drivers such as Ea Fee or Spi Flash adapters. This layered approach keeps NvM hardware independent.

The main collaborators of NvM are the RTE and application software components, the MemIf interface that abstracts EEPROM and flash, flash or EEPROM drivers for direct device access, and the Diagnostic Event Manager for error reporting. These interactions ensure that higher level software remains independent of hardware details while still benefiting from robust memory handling.

For example, when an application requests to store calibration data, the call passes through the RTE into NvM, which then routes the request via MemIf to the appropriate driver, while also monitoring CRC checks to guarantee data integrity. Similarly, if a CRC mismatch or block failure occurs at the driver level, NvM communicates this error to the Diagnostic Event Manager, which can log the issue or trigger a fault response strategy at the system level.

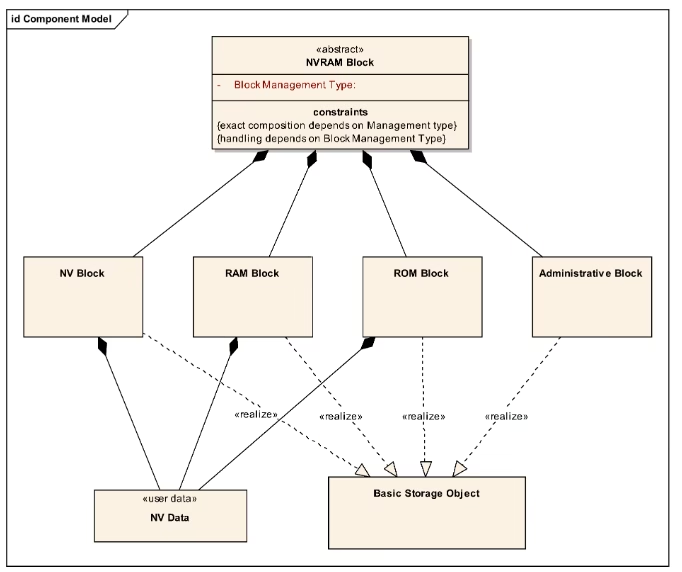

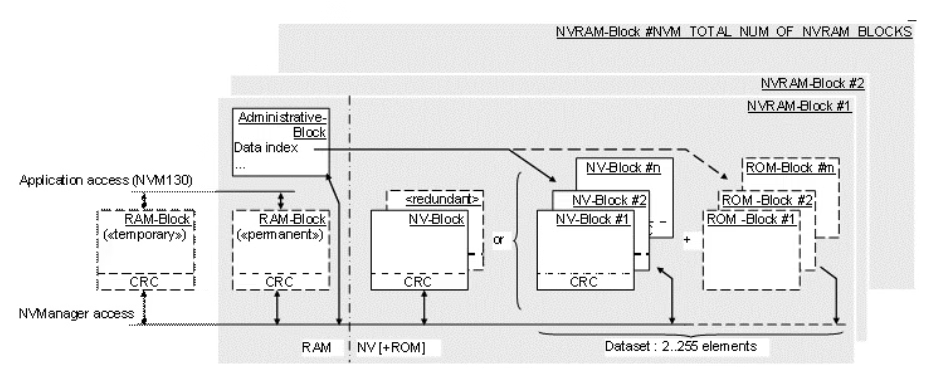

Basic Storage Object

To understand the memory stack, it is important to know the concept of basic storage objects and block management. A basic storage object is the smallest unit of a memory block. The main types of storage objects are: RAM block, ROM block, NV block, and Administrative block.

Memory blocks are used to store and manage data in NV memory. For example, if you have vehicle speed (Vspeed) data of 2 bytes, a dedicated NV block is reserved in NV memory to store this value.

Applications (SWCs) use RAM blocks to handle such data. You may wonder why RAM blocks are needed if NV blocks already exist. The reason is that NV memory has limited write cycles (around 10,000 writes). To protect NV memory and extend its lifetime, data is first stored in RAM blocks.

When a write operation is required, the data is copied from the RAM block into the NV block. Similarly, during a read operation, data is copied from the NV block to the RAM block for the SWC to use. This approach ensures efficient handling and longer durability of NV memory.

The memory stack is built from several basic storage objects, each serving a specific role:

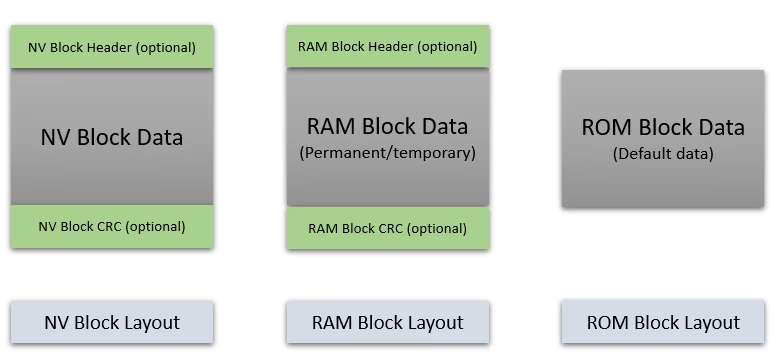

NV Block

An NV Block is the fundamental storage unit in non-volatile memory. It consists of NV memory along with an optional header and an optional CRC.

RAM Block

A RAM Block is a storage object located in RAM. It can be permanent or temporary, and each RAM Block corresponds to a specific NV Block. A RAM Block may include an optional header and an optional CRC (if its corresponding NV Block uses CRC).

ROM Block

A ROM Block is stored in ROM and contains default data. It does not have a header or CRC. The default data in the ROM Block is used during error recovery, when the corresponding NV Block data is found to be invalid.

Administrative Block

The Administrative Block is a mandatory storage object that resides in RAM. It maintains the status information of the associated RAM Block and is essential for managing memory operations.

Block Management Types

In the previous section, we discussed the basic storage objects. This section explains the different block management types.

An NVRAM block is composed of a RAM Block, ROM Block, NV Block, and an Administrative Block. By combining these storage objects in various ways, different types of NVRAM blocks can be configured.

The NVRAM Manager in AUTOSAR (NvM) supports the following block management types:

Native Block

The Native NVRAM Block is the simplest block management type. It allows storing and retrieving data from NV memory with minimal overhead.

In this configuration, one NV Block is created in NV memory, supported by one RAM Block (to provide runtime access for the application), one ROM Block (to store default values), and one Administrative Block (to manage block status).

Configuration:

- NV Block: 1

- RAM Block: 1

- ROM Block: 1

- Administrative Block: 1

Redundant Block

The Redundant NVRAM Block builds on the Native Block by adding fault tolerance and reliability. It protects data against corruption by storing two identical NV Blocks. If one NV Block becomes invalid, data can still be retrieved from the other, ensuring data security and availability.

Here, two NV Blocks are maintained, while only one RAM Block is needed since the application requires a single valid copy of data. A ROM Block can be included to provide default values, along with one Administrative Block.

Configuration:

- NV Block: 2

- RAM Block: 1

- ROM Block: 0 or 1

- Administrative Block: 1

Dataset Block

The Dataset NVRAM Block consists of an array of equally sized NV or ROM Blocks. At any given time, the application can access only one dataset element. The desired dataset element is selected by calling the API NvM_SetDataIndex.

This configuration allows flexible handling of multiple datasets, such as different calibration values or parameter sets.

Configuration:

- NV Block: 1…n

- RAM Block: 1

- ROM Block: 0 or n

- Administrative Block: 1

Key responsibilities and services

NvM provides these major services:

- Initialization and module configuration validation.

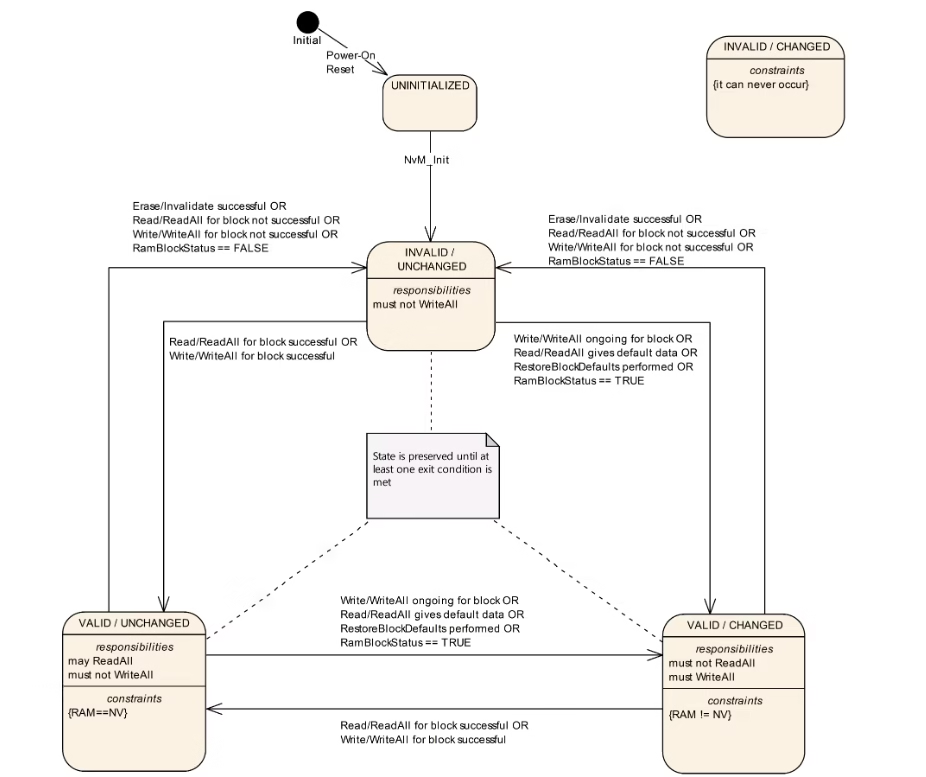

- Read and write operations for defined NVRAM blocks.

- Block management functions such as erase invalidate restore defaults and erase all.

- Integrity checking using CRC or checksums and redundancy handling for redundant blocks.

- Job scheduling and sequencing for memory operations with support for asynchronous job status reporting.

- Support for block types including immediate commit blocks dataset blocks and redundant blocks.

Data integrity and recovery

NvM implements several mechanisms to protect data:

- Header information for each NV block that includes block id version and state. NvM checks this at read time.

- CRC or checksum validation to detect corruption. If CRC fails NvM can try redundant copies or restore ROM defaults if configured.

- Error reporting to the Diagnostic Event Manager when integrity or redundancy is lost.

- Recovery paths that set job results like restored from ROM or redundancy lost to allow higher layers to react.

Job model and runtime behavior

Memory devices are slow and have wear limits so NvM exposes synchronous and asynchronous services and a job-based model:

- Write and read requests produce NvM jobs. Jobs are scheduled and run via lower layer MemIf service calls.

- Job results are reported back via standardized status codes such as request ok integrity failed or redundancy failed.

- NvM supports read all and write all operations used during ECU start up shutdown or diagnostics to process a selected subset of blocks.

- Callbacks and init callbacks are supported so that application RAM can be reinitialized from ROM or other sources during recovery.

Configuration and tooling

NvM behavior is entirely driven by configuration data usually generated by an AUTOSAR tool chain. Typical elements include:

- Block size and physical addressing.

- Management type and use of CRC and redundancy.

- RAM block pointers or callback references for explicit synchronization.

- Processing order and flags such as process in read all or write all.

Tool vendors such as MathWorks Vector and Elektrobit provide tooling or examples to generate the required configuration and glue code for NvM.

Performance considerations and device constraints

When designing NvM usage, factors such as flash erase and write granularity, device endurance, atomicity, power failure windows, scheduling of writes, and block packing must be carefully considered.

Designers should minimize small frequent writes and instead use buffered commit strategies, while critical counters may require redundant blocks or journaling at the application level to guarantee data consistency after unexpected resets. It is also essential to schedule write operations during low load windows to avoid timing interference with real time tasks and to align block sizes with device page sizes to reduce wasted flash space.

For example, writing a 2-byte parameter directly to flash without alignment could cause an entire flash page to be reprogrammed, reducing endurance, whereas grouping parameters into aligned blocks minimizes wear.

Similarly, in safety critical systems such as airbag controllers, redundant blocks combined with CRC validation are commonly used to ensure data remains valid even under repeated power cycles and harsh operating conditions.

Typical implementation patterns

Common implementation patterns in NvM include using permanent RAM blocks with periodic commits to NV for calibration data that changes occasionally, employing redundant blocks with CRC for safety critical parameters where corruption has a high cost, applying wear leveling in the flash driver for frequently changing counters, and providing explicit restore defaults callbacks so the application can reset to a safe state after integrity failures.

These patterns balance reliability with memory endurance by ensuring that NV writes are performed only when necessary and that data integrity is preserved through redundancy and verification.

For example, engine calibration values are often stored in permanent RAM blocks and committed at controlled intervals to avoid flash wear, while odometer counters may use wear leveling schemes so that updates are evenly distributed across memory cells.

In critical domains such as braking or airbag systems, redundant storage combined with CRC checks ensures that even if one memory copy becomes corrupted, the system can recover from the backup without compromising safety.

Verification and testing

AUTOSAR includes acceptance tests for BSW modules and vendors commonly provide compliance tests for NvM. Test scenarios include power cut during a write, corrupted CRC, and loss of redundancy. Diagnostic reporting and correct job status values are key acceptance criteria.

In addition, performance tests are often carried out, such as repeated write and erase cycles to evaluate flash endurance, or stress tests where multiple read and write requests are triggered simultaneously to check scheduling efficiency and data integrity under high load.

Industry adoption

AUTOSAR was founded in 2003 by major OEMs and suppliers to create common standards for E/E software. The NVRAM Manager in AUTOSAR has been part of the Classic Platform since early releases and continues to be maintained in modern releases. Major tool and supplier ecosystems such as Vector, Renesas, Bosch, Elektrobit and MathWorks integrate NvM support in their AUTOSAR tool chains.

Its long-standing presence and continuous updates demonstrate the importance of reliable non-volatile data handling in modern ECUs. As vehicles move toward greater electrification and autonomous features, robust NVRAM management will remain a cornerstone for safety, consistency, and long-term system reliability.