Validating ECUs is vital for vehicle performance, safety and compliance. ECU validation ensures that communication between the control unit and diagnostic tools is accurate, secure and aligned with specification documents and industry standards. Diagnostics protocols are used to validate ECUs Using UDS and OBD-II.

It also verifies that fault detection, reporting and clearing functions work as intended under real world driving conditions. Proper validation using these protocols helps meet regulatory requirements such as emissions compliance and functional safety (ISO 26262) guidelines. It also allows engineers to optimize system performance by fine tuning diagnostic response times and ensuring seamless integration with other vehicle systems.

Modern vehicles may include up to 100 ECUs, which highlights the need for unified diagnostics like UDS. UDS is mandated across all new ECUs produced by Tier-1 OEM suppliers. This scale of integration means that diagnostic protocols must handle large volumes of network traffic without introducing latency that could impact control functions.

For example, in a high-end passenger vehicle with multiple powertrain, body and infotainment ECUs, coordinated diagnostic sessions must be scheduled to prevent bus overload during maintenance or over the air updates. Industry reports show that the use of standardized protocols like UDS reduces development and validation time by enabling reuse of test cases across ECU platforms.

Table of Contents

What Is UDS?

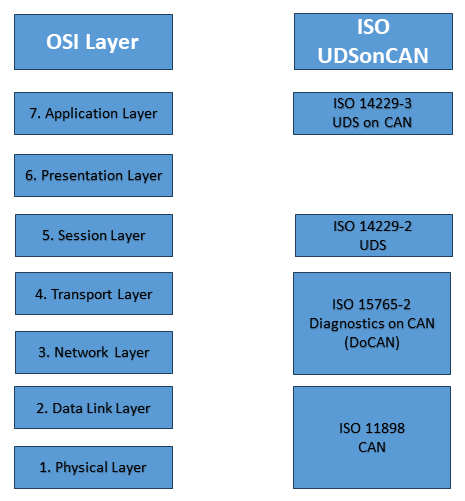

Unified Diagnostic Services (UDS), defined under ISO 14229-1, is a standardized diagnostic communication protocol widely used across ECUs and integrated in AUTOSAR architectures. UDS operates at the session (OSI layer 5) and application layer 7 levels (ISO 14229-3 UDS on CAN), beyond what CAN provides.

It enables operations such as:

- Reading and clearing Diagnostic Trouble Codes

- Firmware updates (download/upload)

- Input/output control and routine execution

- Security access and authentication

In practical applications, the ‘Read Data By Identifier’ 0x22 service can be used to retrieve live engine parameters such as coolant temperature, engine RPM or fuel rail pressure with precise scaling factors applied. The ‘Security Access’ 0x27 service is often implemented with multi stage seed key algorithms to protect critical ECU functions against unauthorized reprogramming.

Engineers performing firmware updates rely on UDS to manage memory segmentation and data integrity verification through CRC checks before activating new software. For example, during routine execution testing, UDS can trigger an actuator like an EGR valve to confirm proper mechanical response under controlled lab conditions. In advanced scenarios, integration with AUTOSAR Diagnostic Communication Manager allows UDS diagnostic services to operate seamlessly over different physical layers such as CAN, FlexRay or Ethernet, improving flexibility in complex vehicle architectures.

What Is OBD-II?

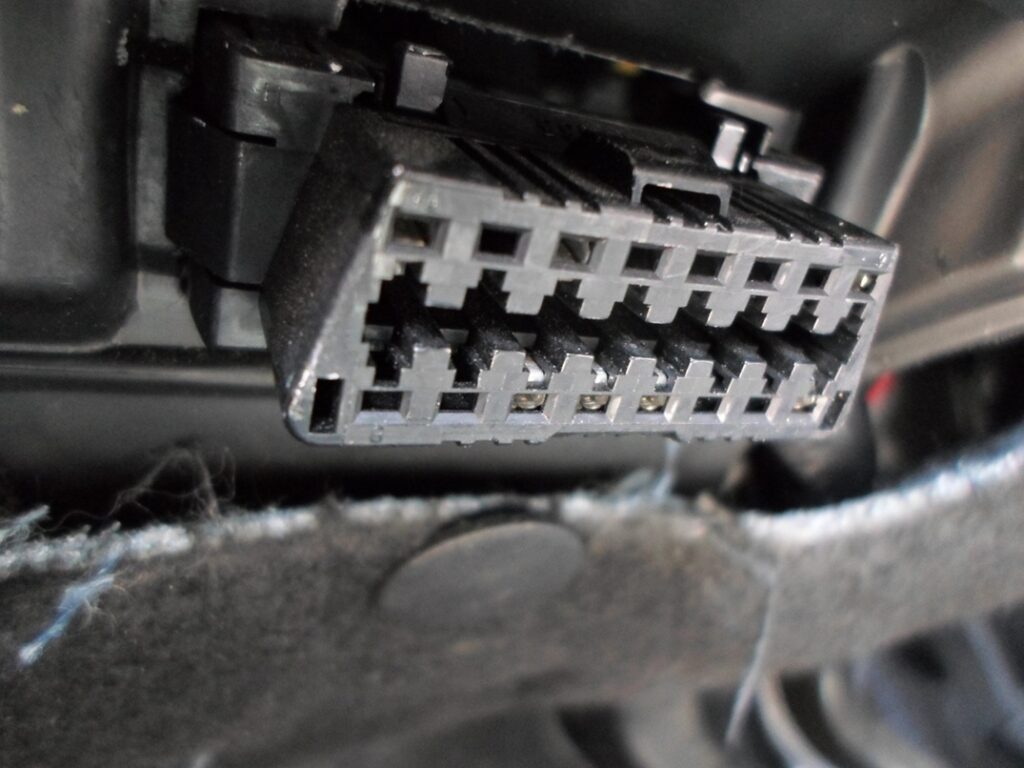

On Board Diagnostics (OBD II), mandated for emission control diagnostics in vehicles, uses standards like SAE J1979 OBD-16 pin connectors and various signaling protocols such as J1850 PWM and VPW, ISO 9141 2, KWP2000 and ISO 15765 CAN. OBD focuses on emission related fault codes and readiness monitoring. In practical testing, engineers use OBD to retrieve standardized Parameter IDs which can provide real time values like oxygen sensor voltage, catalytic converter efficiency and manifold absolute pressure.

The OBD-II protocol defines 10 standard diagnostic modes, labelled from Mode $01 to Mode $0A, each serving a specific function for vehicle diagnostics. These modes allow access to current sensor data, freeze frame data, stored and pending fault codes, as well as test results for oxygen sensors and onboard monitoring tests. They also include commands to clear fault codes, control certain onboard systems and retrieve vehicle information like the VIN. Together, these modes provide a comprehensive framework for communicating with the vehicle’s ECU to monitor performance, diagnose issues and ensure emissions compliance.

The system also supports freeze frame data capture, which records a snapshot of sensor values and operating conditions at the moment a fault is detected, aiding in root cause analysis. Readiness monitors in OBD track the status of systems such as the evaporative emission control system and secondary air injection, ensuring that they have been tested and are functioning properly.

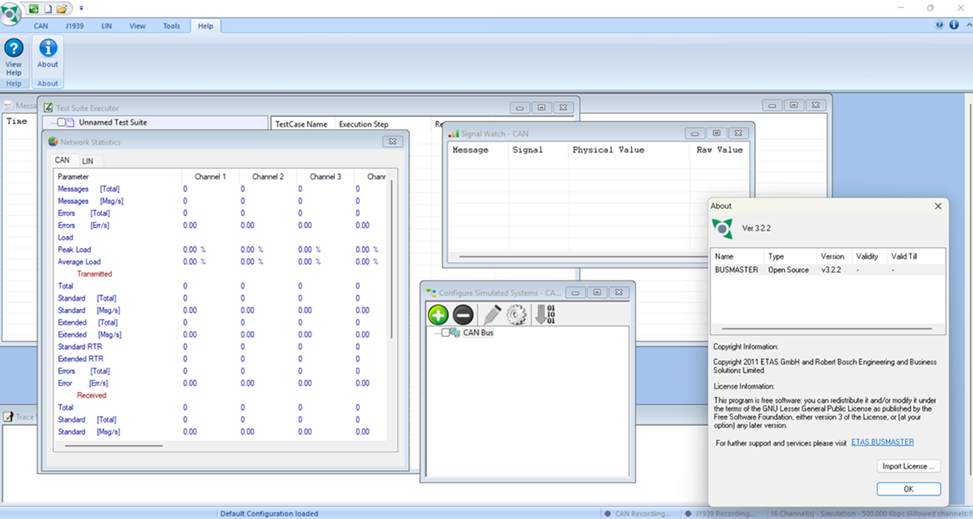

Validation through Manual Testing

Testers manually send UDS requests such as session control or DID read using BusMaster tool or Vector’s CANoe and inspect responses. This method is meticulous but slow and error prone. Manual validation allows engineers to directly observe ECU behavior in response to specific diagnostic commands, which is useful for isolating complex issues. These diagnostic responses are validated against the Test Specification documents or ISO standard docs.

For example, sending a 0x10 Diagnostic Session Control request and monitoring the timing and content of the ECU’s positive response can reveal issues in session transition logic. Engineers may also manually alter input conditions such as supply voltage or sensor readings to verify how the ECU handles diagnostic requests under varying operating states.

In some cases, manual testing is used to validate rare scenarios such as security access challenges where seed key (service 0x27) exchanges must be confirmed step by step. Additionally, manual testing is valuable when validating DTC handling by injecting fault conditions and confirming correct trouble code reporting and clearing behavior. Testers may also manually initiate firmware download sequences to verify that the ECU correctly enters programming mode and handles block transfers.

Furthermore, manual interaction is often required during exploratory testing to identify undocumented behaviors or vendor specific extensions to standard UDS services. However, while this approach provides valuable insights, it is often complemented by automated testing to increase coverage and reduce human error in large scale validation projects.

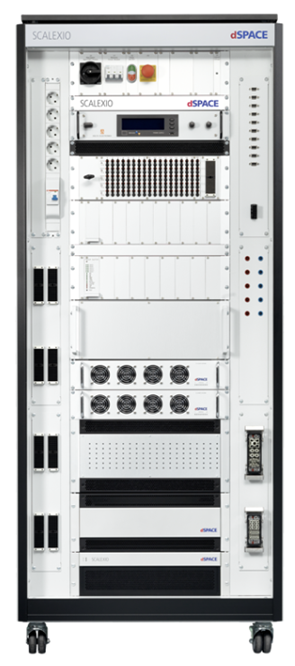

Validation through Automated Testing (HIL-Based)

More efficient validation leverages HIL tools like Vector CANoe, Vector VT System, dSPACE, LabVIEW and Simulink. These tools automate test sequences derived from standards such as diagnostics files (*.ODX or Vector specific format *.CDD) and DBC files. Benefits include scalable and repeatable test coverage and support for multiple UDS services such as session control, DTC management, security, routines and firmware transfer.

In practice, a HIL system can simulate complete vehicle network traffic while injecting diagnostic commands, allowing engineers to evaluate ECU behavior under realistic load conditions. For example, a firmware transfer test can be executed automatically with verification of data block integrity and reprogramming times, ensuring compliance with ISO 14229 timing constraints.

Automated testing can also simulate transient faults on communication buses to confirm that the ECU maintains diagnostic availability during network disturbances. By integrating with continuous integration frameworks, HIL setups can run regression test suites overnight, producing detailed reports on pass fail status, timing margins and protocol compliance. This approach greatly reduces manual intervention while ensuring consistent execution of complex diagnostic scenarios across multiple ECU variants.

Additionally, automated tests can perform stress testing by flooding the bus with high priority messages to verify that the ECU’s diagnostic response times remain within specified limits. Some HIL systems can emulate sensor signal variations dynamically during test runs to evaluate how the ECU adapts its diagnostics under different environmental conditions. Furthermore, automated security access workflows can validate multi stage seed key algorithms by systematically testing authorized and unauthorized key sequences. These capabilities enable comprehensive coverage that would be impractical with manual testing alone, significantly improving validation quality and speed.

Key Validation Scenarios

Key validation scenarios for ECU testing under UDS and OBD protocols require precise execution and analysis to ensure conformance and robustness. Session access validation involves testing transitions between default, programming, extended and safety sessions, verifying that each session grants only the intended permissions while preventing unauthorized access to sensitive commands.

Security mechanisms must be thoroughly validated by simulating both correct and incorrect seed/key challenges, analyzing system behavior under failed authentication attempts and confirming lockout timers or incremental delays to deter brute force attacks. DTC operations should be examined by injecting fault conditions, verifying that Diagnostic Trouble Codes are stored accurately with proper timestamps, confirming that clearing functions reset the fault memory without affecting unrelated data and assessing DTC aging logic over multiple ignition cycles.

Firmware upload and download processes should be tested by transferring large binary files in segmented blocks, verifying that flow control and block sequencing operate reliably under varying network loads and confirming that post-transfer checksum or CRC validation prevents corrupted firmware from being accepted. This rigorous validation ensures that the ECU not only meets functional requirements but also maintains security, reliability and regulatory compliance in real-world operating conditions.

Final Thoughts

Validating ECUs using UDS and OBD-II protocols requires mastering both protocol mechanics and test strategies. Start with a foundational understanding of UDS sessions, SIDs and security, along with OBD regulatory fault codes and signalling differences. Implement manual tests for early validation, then scale to automated HIL based testing using ODX and DBC integration for comprehensive coverage.

Focusing on session control, security, DTC lifecycle and firmware updating ensures robust and compliant ECU implementations. Combining both protocols allows verification of regulatory compliance and advanced diagnostics, which is critical in mixed protocol networks. For example, a powertrain ECU may use UDS for software updates while relying on OBD for emissions monitoring, requiring careful bus management.

Precise timing analysis confirms that service responses meet ISO limits even under heavy load. Automated regression testing in production helps prevent communication errors after firmware updates. An optimized validation strategy improves reliability and speeds up development by catching issues before vehicle integration.