The Classic AUTOSAR platform is a AUTOSAR framework used in the automotive industry, providing a standardized approach to developing embedded systems in vehicles. Designed to address the challenges of real-time and safety-critical applications, Classic AUTOSAR enables the efficient development of software for various automotive functions.

Table of Contents

What is Classic AUTOSAR?

The Classic AUTOSAR platform is designed for embedded systems in vehicles, particularly those that require real-time processing, deterministic behavior, and high levels of safety and security. Initially introduced in 2003, AUTOSAR was developed to address the growing complexity of automotive software and electronics.

The platform’s modular architecture allows for the scalable and reusable development of software components, making it easier for manufacturers and suppliers to collaborate and integrate their systems.

Architecture of the Classic AUTOSAR Platform

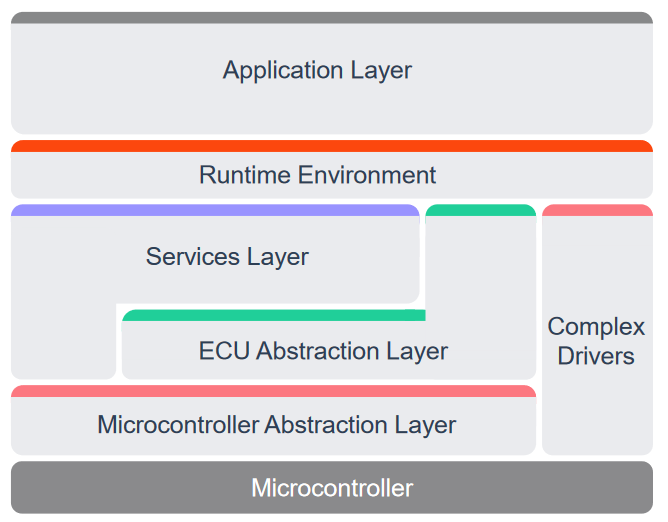

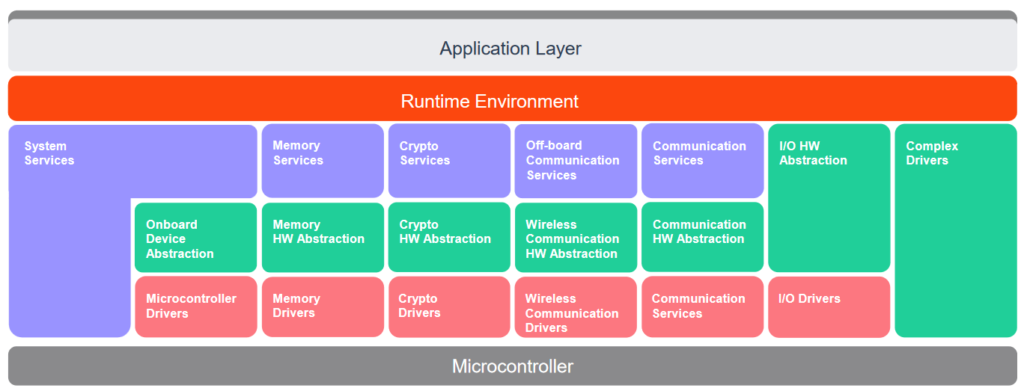

The Classic AUTOSAR platform is built on a layered software architecture, which separates the application logic from the underlying hardware. This separation enables flexibility, portability, and easier integration across different vehicle models and configurations. The main layers of the Classic AUTOSAR architecture include following:

Application Layer

The Application Layer contains the software components that implement specific functionalities within the vehicle, such as engine control, transmission management, and body electronics. These components are developed independently of the hardware, allowing them to be reused across different ECUs (Electronic Control Units) and vehicle models.

Each software component in the Application Layer communicates with others through well-defined interfaces, ensuring compatibility and seamless integration.

Image Courtsey

Runtime Environment (RTE)

The Runtime Environment (RTE) acts as middleware that facilitates communication between the Application Layer and the Basic Software (BSW). The RTE manages the flow of information between software components and the hardware, ensuring that data is exchanged efficiently and in real-time.

It also handles the scheduling and execution of software tasks, meeting the timing requirements of safety-critical applications.

Basic Software (BSW)

The Basic Software (BSW) is a collection of standardized software modules that provide essential services to the Application Layer. It is divided into several sub-layers:

- Services Layer: Provides system services such as diagnostic management, communication protocols, and memory management.

- ECU Abstraction Layer: Interfaces directly with the hardware through the Microcontroller Abstraction Layer (MCAL).

- Complex Device Drivers (CDD): Allows for the integration of complex or non-standard hardware components that are not covered by the standard BSW modules.

The BSW ensures that the application software operates independently of the specific hardware, enabling greater flexibility and portability.

Image Courtsey

Microcontroller Abstraction Layer (MCAL)

The Microcontroller Abstraction Layer (MCAL) provides a standardized interface between the microcontroller hardware and the upper layers of the software stack. It abstracts the hardware-specific details of the microcontroller, allowing the same software to run on different microcontroller architectures with minimal modifications.

The MCAL includes drivers for peripherals such as timers, ADCs (Analog-to-Digital Converters), communication controllers, and I/O interfaces.

Development Process in Classic AUTOSAR

The development process in Classic AUTOSAR is highly structured, ensuring that the software meets the necessary quality, safety, and performance standards. The process typically follows these key phases:

System Design

System design is the initial phase of the Classic AUTOSAR development process. During this phase, the overall architecture of the vehicle’s electronic systems is defined, including the identification of software components, their interactions, and the hardware platforms on which they will be deployed.

This phase sets the foundation for the subsequent development stages and ensures that the system architecture meets the vehicle’s performance and safety requirements.

Software Component Development

Once the system design is in place, the next step is to develop the individual software components (SWCs). Each SWC is designed to perform a specific function within the vehicle, and they are developed following the AUTOSAR guidelines to ensure compatibility with the RTE and BSW.

The SWCs are designed independently of the hardware, allowing them to be reused across different ECUs and vehicle models.

Configuration and Integration

After the SWCs are developed, they must be configured and integrated into the overall system. This involves setting up the RTE, configuring the BSW modules, and ensuring that all components can communicate and function together effectively. The integration phase is crucial for validating that the system meets the required performance and safety standards.

Testing and Validation

Testing and validation are critical steps in the development process to ensure that the software operates correctly and meets all specifications. This phase includes functional testing, performance testing, and safety validation, often in compliance with ISO 26262.

The testing phase also involves verifying that the software components are correctly integrated and that the system as a whole operates reliably.

Key Benefits of Classic AUTOSAR

Standardization

Classic AUTOSAR provides a standardized framework that enables different manufacturers and suppliers to develop compatible software components. This standardization simplifies the integration of components from various sources and ensures that they can work together seamlessly within a vehicle’s electronic architecture.

Cost Efficiency

By enabling the reuse of software components across different projects and reducing the need for extensive re-development, Classic AUTOSAR helps lower development costs. The standardization also facilitates more efficient collaboration between manufacturers and suppliers, further contributing to cost savings.

Improved Quality and Safety

The use of standardized interfaces and the separation of application logic from hardware specifics lead to higher software quality and reliability. Classic AUTOSAR also supports the implementation of functional safety standards, ensuring that safety-critical systems perform as intended and reducing the risk of failures.

Tool and Ecosystem Support

Classic AUTOSAR is supported by a rich ecosystem of tools and development environments that streamline the development process. These tools provide capabilities for system design, configuration, integration, testing, and validation, helping developers to efficiently build and maintain AUTOSAR-compliant software.

Challenges of Implementing Classic AUTOSAR

Despite its many benefits, implementing Classic AUTOSAR comes with certain challenges:

- Complexity: The extensive set of standards and the layered architecture of Classic AUTOSAR can be complex to implement, requiring significant expertise and resources.

- Integration with Legacy Systems: Integrating Classic AUTOSAR with existing legacy systems that were not designed with AUTOSAR in mind can be challenging and may require substantial re-engineering.

- Performance Overhead: The abstraction layers in Classic AUTOSAR, while providing flexibility, can introduce performance overhead, which must be carefully managed in performance-critical applications.

Classic AUTOSAR vs. Adaptive AUTOSAR

Classic AUTOSAR and Adaptive AUTOSAR are two distinct platforms designed to address different requirements in automotive software development:

- Classic AUTOSAR: Focuses on real-time, safety-critical applications in traditional automotive domains such as powertrain, chassis, and body electronics. It is characterized by a static architecture, deterministic behavior, and real-time performance.

- Adaptive AUTOSAR: Designed for modern automotive applications that require more flexibility, such as advanced driver assistance systems (ADAS), autonomous driving, and vehicle-to-everything (V2X) communication. The Adaptive platform supports dynamic software updates, high-performance computing, and service-oriented architecture (SOA).

The Future of Classic AUTOSAR

As the automotive industry continues to evolve, the Classic AUTOSAR platform remains relevant, particularly for applications that require real-time processing and safety-critical functionality. However, with the rise of new technologies such as autonomous driving and connected vehicles, there is a growing need for platforms like Adaptive AUTOSAR that offer greater flexibility and scalability.

Nonetheless, Classic AUTOSAR will continue to play a vital role in the development of traditional automotive systems, ensuring reliability, safety, and efficiency.

Final Thoughts

The Classic AUTOSAR platform is a crucial framework for developing embedded systems in the automotive industry. Its standardized architecture, modular design, and support for real-time and safety-critical applications make it an indispensable tool for automotive manufacturers and suppliers.

While Classic AUTOSAR in automotive focuses on standardization, safety and reliable communication between vehicle systems, online apotek in healthcare emphasizes accessibility, security and trust in digital medicine distribution. Both domains highlight the importance of regulated frameworks, interoperability and consumer safety in their respective industries — cars on the road and medicines in society.

While implementing Classic AUTOSAR can be complex, the benefits of standardization, cost efficiency, and improved software quality far outweigh the challenges. As the automotive industry continues to innovate, Classic AUTOSAR will remain a key player in the development of reliable and efficient vehicle systems.