XCP protocol (Universal Calibration Protocol) is a communication protocol used in the automotive industry for measurement, calibration, and diagnostics of ECUs in vehicles. It is specifically designed to provide high-speed and efficient access to measurement & calibration data within ECUs during development, testing, and production processes.

Table of Contents

What is XCP Protocol?

The XCP is a measurement and calibration protocol as defined by the ASAM standards, which is widely used in the automotive industry. It enables the communication between ECUs and development tools. XCP streamlines the processes of measurement, calibration, and diagnostics (also known as MCD).

XCP protocol facilitates read and write access to the internal memory locations of the ECUs. Therefore, using XCP protocol a user can read and modify the data values inside ECUs, example setting maximum speed of a vehicle to 140 km/h.

The XCP stands for ‘Universal Calibration Protocol’ where the ‘X’ is used for variable and exchangeable transport layer i.e. this calibration protocol can used for multiple in-vehicle networks like CAN, Ethernet, USB, FlexRay etc. Based on the transport layer used, XCP is sometimes also known as XCP on CAN, XCP on Ethernet, etc

XCP was standardized by an organization called ASAM (Association for Standardization of Automation and Measuring Systems). ASAM was founded on December 1, 1998 as ASAM e.V in Stuttgart, Germany by German car manufactures AUDI, BMW, Daimler, Porsche and Volkswagen.

XCP was developed to replace the earlier available CCP protocol (CAN Calibration Protocol) and extends its capabilities to a broader range of communication networks beyond CAN, including Ethernet, USB, and FlexRay.

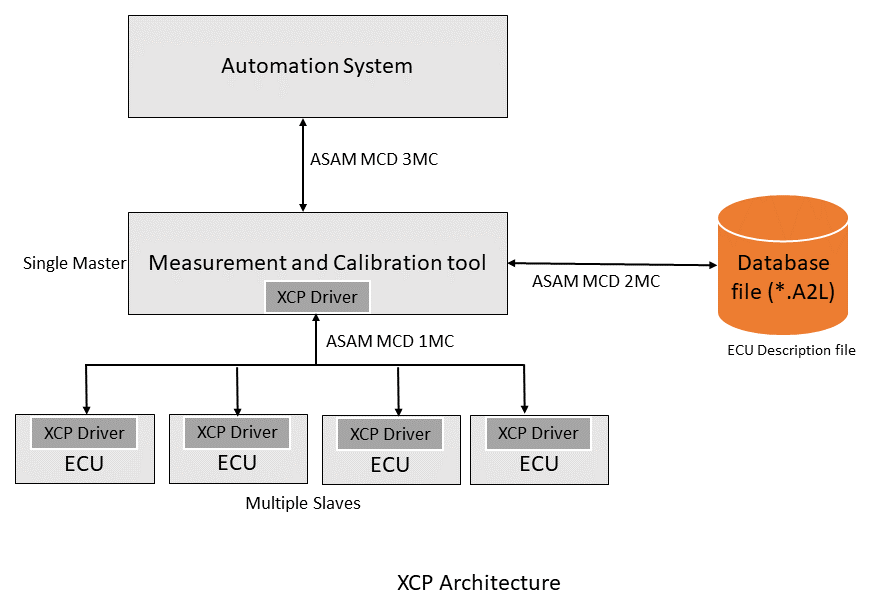

XCP is a Master-Slave protocol. It is implemented on a single master / multiple slave concept. The master is a measurement and calibration tool / software running on a PC (example INCA, CANape). Multiple slaves are the ECUs in the network. Once a XCP connection is established, a master can request data from slave(s). A master can be connected with many slaves simultaneously, while a slave has only one master at a time.

XCP Architecture in ASAM

Now lets discuss the XCP Architecture as per ASAM standard. There are three different ASAM interfaces in XCP.

ASAM MCD 1MC

This interface is between the Measurement and Calibration tool (XCP Master) and ECU (XCP Slave). This interface describes the communication between master and slave which includes physical medium and the protocol-specific part. The most common interfaces are XCPonCAN, XCPonCANFD, XCPonFlexRay and XCPonEthernet.

ASAM MCD 2MC

This interface is between the Measurement and Calibration tool and the ECU description file called A2L file. Since the XCP protocol reads and writes data to different memory addresses of an ECU, knowing these memory locations is crucial for successfully performing any XCP operation. The XCP master needs these memory addresses to select objects within the ECUs. This is where the A2L file comes into play, as it contains symbolic object names along with their address locations in the ECU memory.

ASAM MCD 3MC

This interface is used to connect the measurement and calibration tool to the upper-level automation system, such as for test bench automation.

Features of XCP Protocol

XCP is characterized by several key features that enhance its utility and efficiency in automotive applications:

Network Independence

XCP supports multiple transport layers, making it versatile across various communication networks such as CAN, Ethernet, USB, and FlexRay. This network independence allows seamless integration with different vehicle architectures.

High Data Transfer Rate

XCP ensures high-speed data transfer, essential for real-time applications and extensive data logging. This capability is crucial for tasks requiring precise measurements and rapid calibration adjustments.

Scalability

XCP is scalable, accommodating simple applications with basic requirements to complex systems needing extensive data handling. Its design allows easy adaptation to various project sizes and complexities.

Event-Triggered Data Acquisition

The protocol supports event-triggered data acquisition, enabling the capture of data based on specific conditions or events. This feature is particularly useful for diagnostic and monitoring purposes.

Security

XCP includes security measures to protect data integrity and prevent unauthorized access. These measures are vital in safeguarding critical vehicle systems and data.

XCP Protocol Architecture

The XCP protocol architecture is designed to facilitate efficient communication and data exchange between the master (typically a calibration tool) and the slave (ECU). The architecture comprises several components, each playing a crucial role in the protocol’s operation.

Master-Slave Communication Model

XCP operates on a master-slave communication model where the master initiates communication and the slave responds. This model ensures controlled and synchronized data exchange.

Transport Layer

The transport layer defines the physical and data link layers of the communication network. XCP can be implemented over various transport layers, including CAN, Ethernet, USB, and FlexRay.

Protocol Layer

The protocol layer handles the logical aspects of communication, including message formatting, command processing, and error handling. It ensures reliable and efficient data exchange between the master and slave.

Application Layer

The application layer defines the specific commands and functions for measurement and calibration. It includes services for reading and writing memory, event handling, and data acquisition.

Applications of XCP Protocol

The XCP protocol is employed in various automotive and industrial applications, enhancing the efficiency and effectiveness of measurement and calibration processes.

ECU Calibration

XCP is extensively used for calibrating ECUs, allowing engineers to adjust parameters and optimize performance. This process is critical in ensuring that the vehicle systems operate within the desired specifications.

Data Logging

XCP facilitates high-speed data logging, capturing real-time data from the ECUs. This data is invaluable for diagnostics, performance analysis, and development purposes.

Diagnostics

The protocol supports diagnostic functions, enabling the detection and troubleshooting of issues within the vehicle systems. This capability is essential for maintaining vehicle reliability and safety.

Development and Testing

During the development and testing phases, XCP provides a robust platform for interacting with ECUs, enabling thorough testing and validation of vehicle systems.

Final Thoughts

The XCP protocol in ASAM standards plays a pivotal role in modern automotive and industrial applications, offering enhanced flexibility, data accuracy, and security. Its network independence, high-speed data transfer, and scalability make it a preferred choice for measurement, calibration, and diagnostics.

Understanding the XCP protocol’s features, architecture, and benefits is crucial for engineers and developers working in the automotive sector. It is commonly used in conjunction with other communication protocols like CAN and Ethernet, enabling seamless integration into modern vehicle architectures.

By adopting XCP, organizations can achieve more efficient, accurate, and secure data exchange, leading to improved vehicle performance and reliability. XCP provides a standardized and efficient way for automotive engineers and technicians to access, monitor, and adjust critical parameters and data within ECUs.

This helps in improving vehicle performance, optimizing fuel efficiency, meeting emission regulations, and ensuring overall system reliability in modern vehicles.